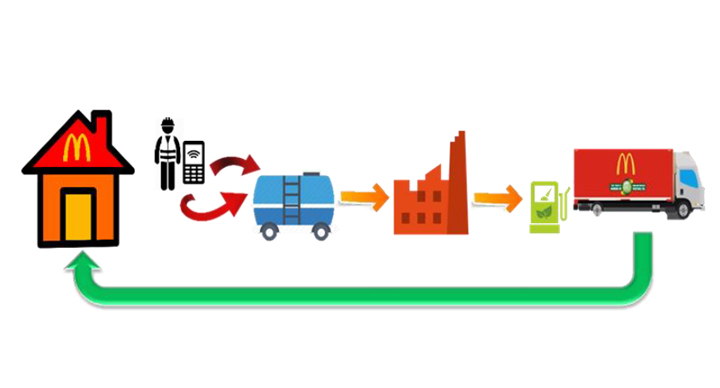

On World Environment Day, we thought it would be apt to talk about a very special initiative of ours. Did you know that a part of our logistics fleet runs on fuel made from our used cooking oil at restaurants? Innovative, right?

So how does it work?

It’s a simple closed loop process. Firstly, we collect used cooking oil in specially designed containers and transport them to a converting unit. At the processing facility of this unit, this oil is left to settle in large tanks. After a while, smaller and lighter particles start floating at the top, while heavier ones start sinking at the bottom of the tanks.

Now we heat the oil and spin it to remove water and solids. This is followed by a process called esterification, a chemical reaction that produces biodiesel. Once the fuel has been produced, it is filtered and distilled. The biodiesel is now all ready to be used by our delivery trucks. The entire conversion process takes about 6 to 8 hours.

Why is bio-diesel better?

It’s good for the earth. Biodiesel is a cleaner fuel with 75% fewer emissions than diesel. Not just that, biodiesel also helps reduce the dependence on finite fossil fuel reserves. In fact, by recycling our used cooking oil, we are saving over 420,000 litres of crude oil annually! Recycling used cooking oil also helps reduce water pollution because disposing this oil leads to clogging of drains.

This initiative is in sync with McDonald’s global motto – “Reduce, re-use, recycle”.

We started this as a pilot last year across our 85 stores in Mumbai. Today we are converting more than 35,000 litres of used cooking oil every month into biodiesel. And this is just the beginning. At the moment, we are one of the only four food companies in India that use 100% biodiesel to fuel their delivery trucks. Our goal is to run our entire fleet of trucks on biodiesel in future. With our partners, we are working hard to make that possible.